13.7 / 35

13.7 hectares of rolling mills

35 hectares of steel mill

820,000

Steel mill production

capacity of 820 KT

620,000

Rolling mill production

capacity of 620 KT

525

Employees

Who we are

LME BELTRAME GROUP is a leading player in the steel industry with a European reach. Located in an urban area in the heart of the Valenciennes and Porte du Hainaut conurbations, the company produces merchant rolled products for more than 600 customers worldwide.

News

History

LME was established in 1875 in Trith-Saint-Léger, near Valenciennes, under the name of its founder: “Maison César Sirot”.The company grew rapidly during the 20th century under the management of Albert Alnot (César Sirot’s son-in-law), and became Métalescaut in 1899. The company became part of the Usinor group in 1975. The Unimétal group, producer of the long steel branch of the Usinor Sacilor group, subsequently took control of almost all of Métalescaut’s capital.

In 1988, the steel groups Usinor Sacilor – Unimétal, Cockerill-Sambre and Arbed created the company “Laminés Marchands Européens”, better known by its acronym LME. LME was then absorbed by SME (Société Métallurgique de l’Escaut) with effect from 1 January 1993. The new entity took the name “Laminés Marchands Européens”.

The company was privatised on 2 June 1994, with the Beltrame Group acquiring a majority stake.

The Usinor Sacilor and Cockerill groups left LME in 1997. The AFV BELTRAME Group currently holds 80.23% of LME’s capital.

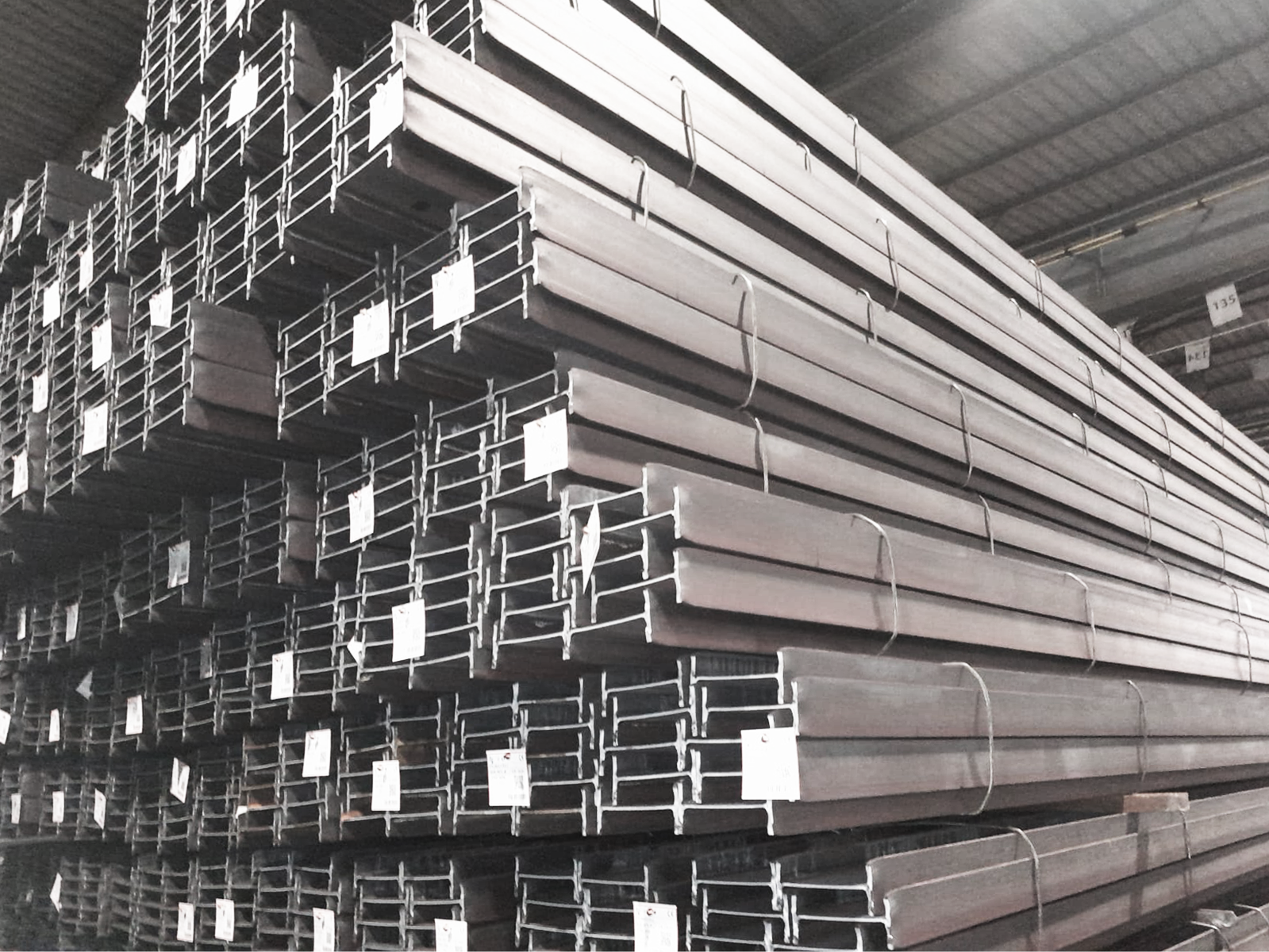

Products

As the market leader in France and the only French producer of merchant bars, LME offers a wide range of products, including flat bars, equal and unequal angles, solid rounds and squares, UACs, Tees, UPNs and IPEs.

Our product range has recently been extended to include concrete reinforcing bars.

Markets

The French market accounts for 27% of sales, followed by the German market (23%) and the European and major export markets (20%). The remainder is divided between the Benelux countries and the United Kingdom.

Management

Job opportunities

Job opportunities

People

With LME undergoing a major structural transformation, we felt it was essential to support all our managers in the day-to-day implementation of consistent managerial practices aimed at generating greater performance, less stress and more pleasure. That’s why, since the end of March, we’ve been rolling out a training program called The Committed Manager, which will involve more than 100 of the company’s managers, including the management team.

Sustainable development

Steel has no impact on the environment when it is used, and can be recycled ad infinitum while retaining its mechanical performance. When it comes to its production, LME is also fully committed to the major challenges of sustainable development:

Circular and local economy: our steel is made entirely from recycled scrap metal. These raw materials come from an average distance of less than 300km and our products are mainly distributed in France and Europe.

LME also aims to maximise the recovery of waste generated by the production of steel, favouring geographically close channels and allowing substitution for natural materials.

Decarbonation: production in electric furnaces emits little CO2 compared with primary production processes (emissions <100 kg/tonne for the production of billets in the steelworks and <80 kg/tonne for the transformation of finished products in the rolling mill - scopes 1 and 2).

In addition to this performance, LME is now working with the Beltrame Group on an ambitious program to reduce these emissions.

Environmental and energy excellence: certified ISO 50001 and ISO 14001, standards focused on the management of environmental and energy improvements in companies, LME is pursuing its commitment through concrete actions and investments (notably aimed at reducing the impact on water and air, the energy performance of equipment and processes, etc.).

Integration into the local area: as an industry located in an urban environment, LME is committed to integrating the site into the local area, in particular through the development of new projects (architectural and landscape integration, etc.) and by promoting its assets (project to recover waste heat from a future urban network, preservation of biodiversity, etc.).

In 2022, a new investment has been made to replace one of our reheating furnaces in the rolling mill (a highly energy-efficient furnace), with a commissioning in february 2023. This project, part-funded by France Relance’s decarbonation aid, make the production line sustainable and reliable, but above all reduce our consumption of natural gas and the associated CO2 emissions.

Safety

Safety is an absolute priority for LME-BELTRAME GROUP, and a major issue for the company, which has set itself the target of zero accidents.

SWATs – Safety Walk and Talk – are designed to effectively improve malfunction situations. How do they do this? During a SWAT, a team of two observes what is happening at a workstation in order to identify positive points as well as risky behaviour that could lead to dangerous situations. The idea is to involve the person concerned each time, in order to work with them to find solutions that will enable them to work safer. SWAT should raise awareness and trigger a change in behaviour. The aim is to give each employee a sense of responsibility and a say in their own safety. Every month, 11 pairs of employees each carry out 1 SWAT.

“Near Miss” is a software application that enables the reporting of malfunctions identified in the field. As soon as a near miss or dangerous situation is identified, a Near Miss declaration must be completed. The challenge is then to implement various corrective actions, thereby reducing the risk of employees being exposed to a hazard.

Cross-audits are carried out every year to assess the application of Group standards on the site. Carried out by an external auditor who is a Group employee, their strength lies in the exchange and sharing of best practice. Around twenty areas are audited in this way: pollution prevention and control, environmental management system, health and safety, incident and near miss reporting, working at height, etc.

Objectives

LME manufactures steel products exclusively from recycled scrap metal. It strives for environmental and energy excellence throughout its production processes.

While stabilising the existing situation, LME is constantly seeking to improve its performance. For example, in 2021, a new investment in one of our reheating furnaces for the rolling mill (a highly energy-efficient furnace) should not only improve productivity but also reduce our CO2 emissions.

It involves all our employees through training courses leading to certification, the sharing of ideas and best practice, both internally and within the Group, and aims to optimise processes.

Contacts

LME BELTRAME GROUP

LAMINÉS MARCHANDS EUROPÉENS S.A.

2, rue Emile Zola, BP 1

59125 Trith Saint Léger (France)

Ph. +33 (0)327 142 020

info.fr@beltrame-group.com

SALES DEPT.

commercial.france@beltrame-group.com