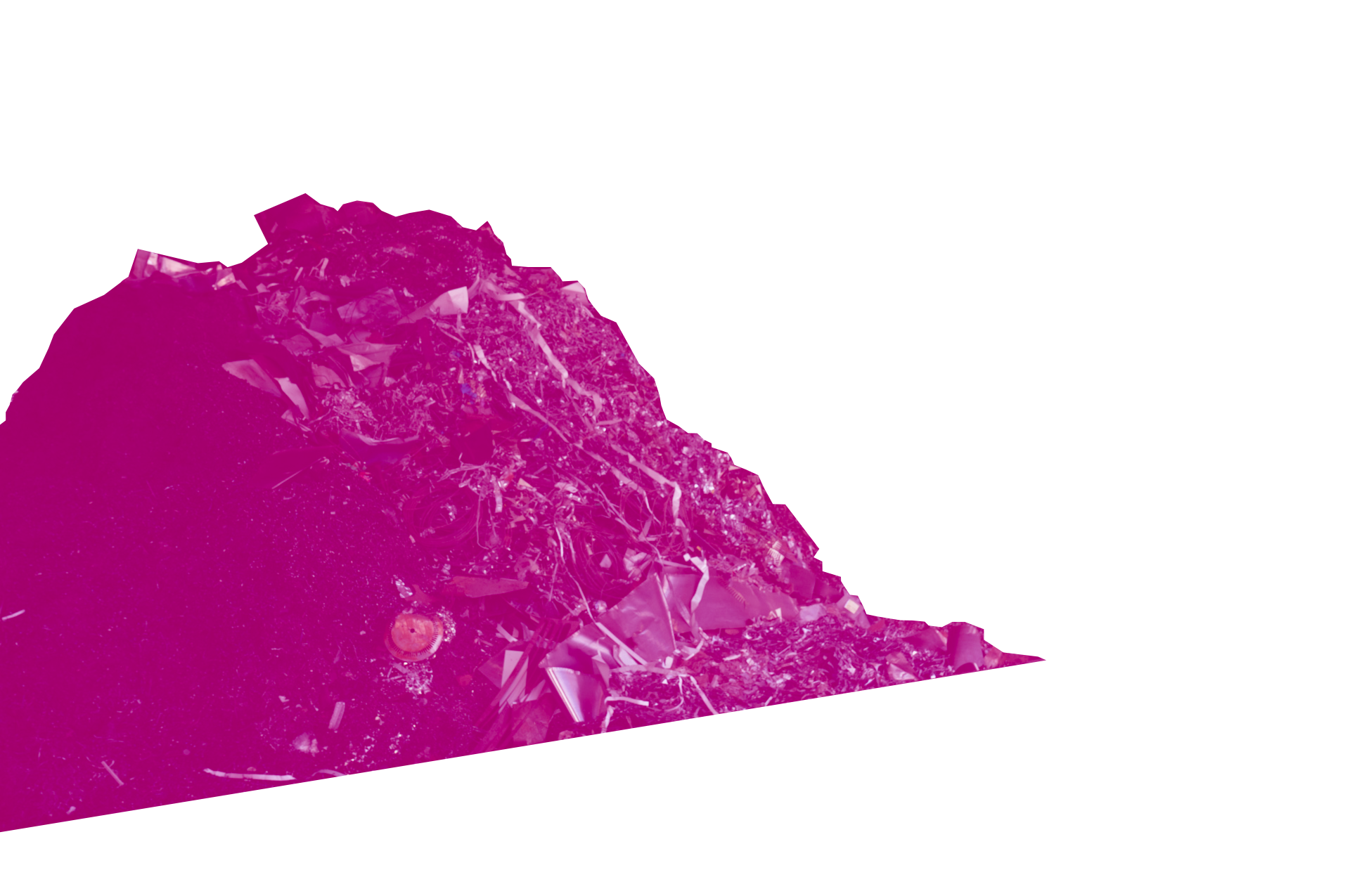

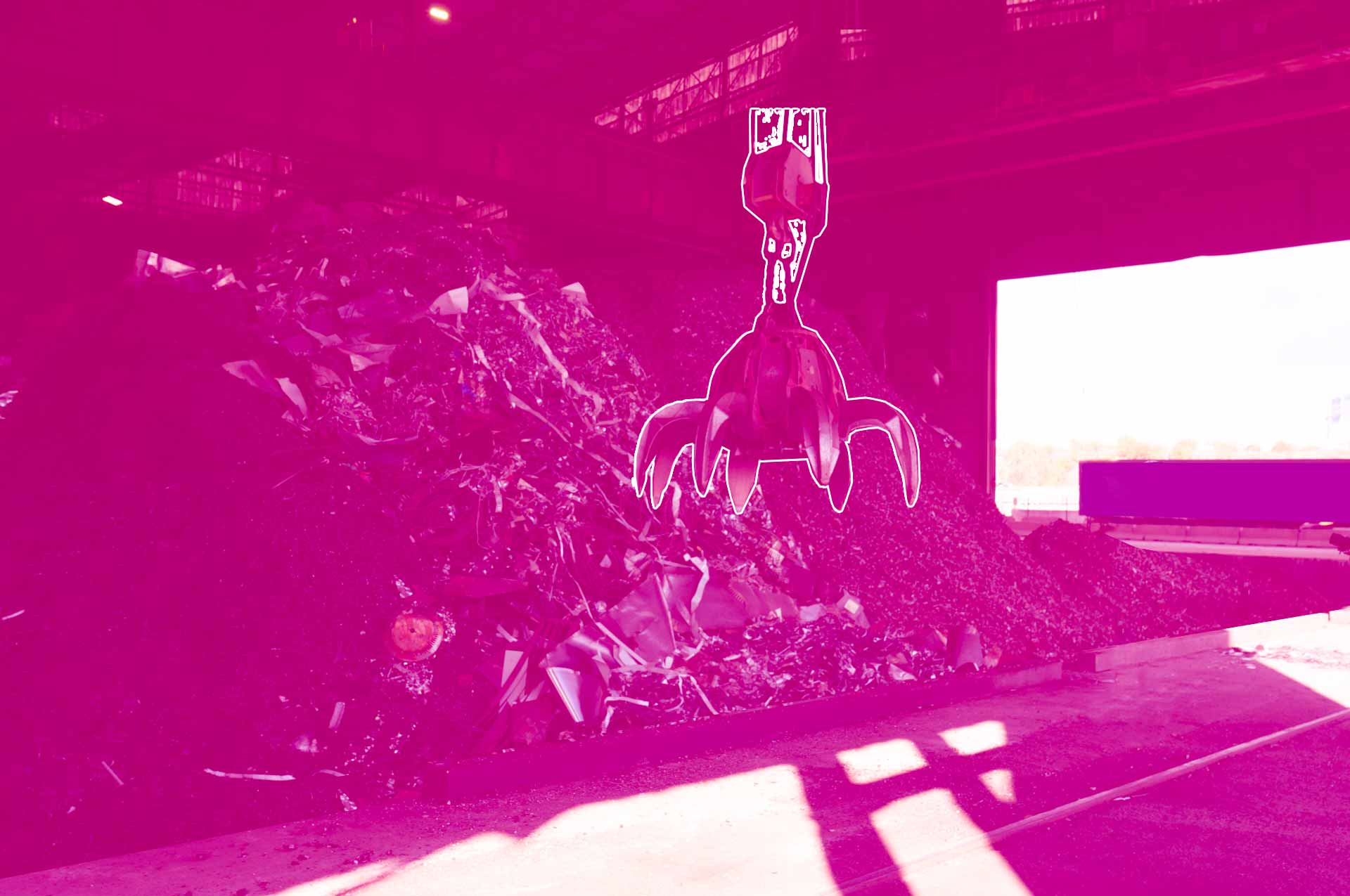

The production process begins with the recovery of raw materials. Scrap is unloaded and selected within the deposit area.

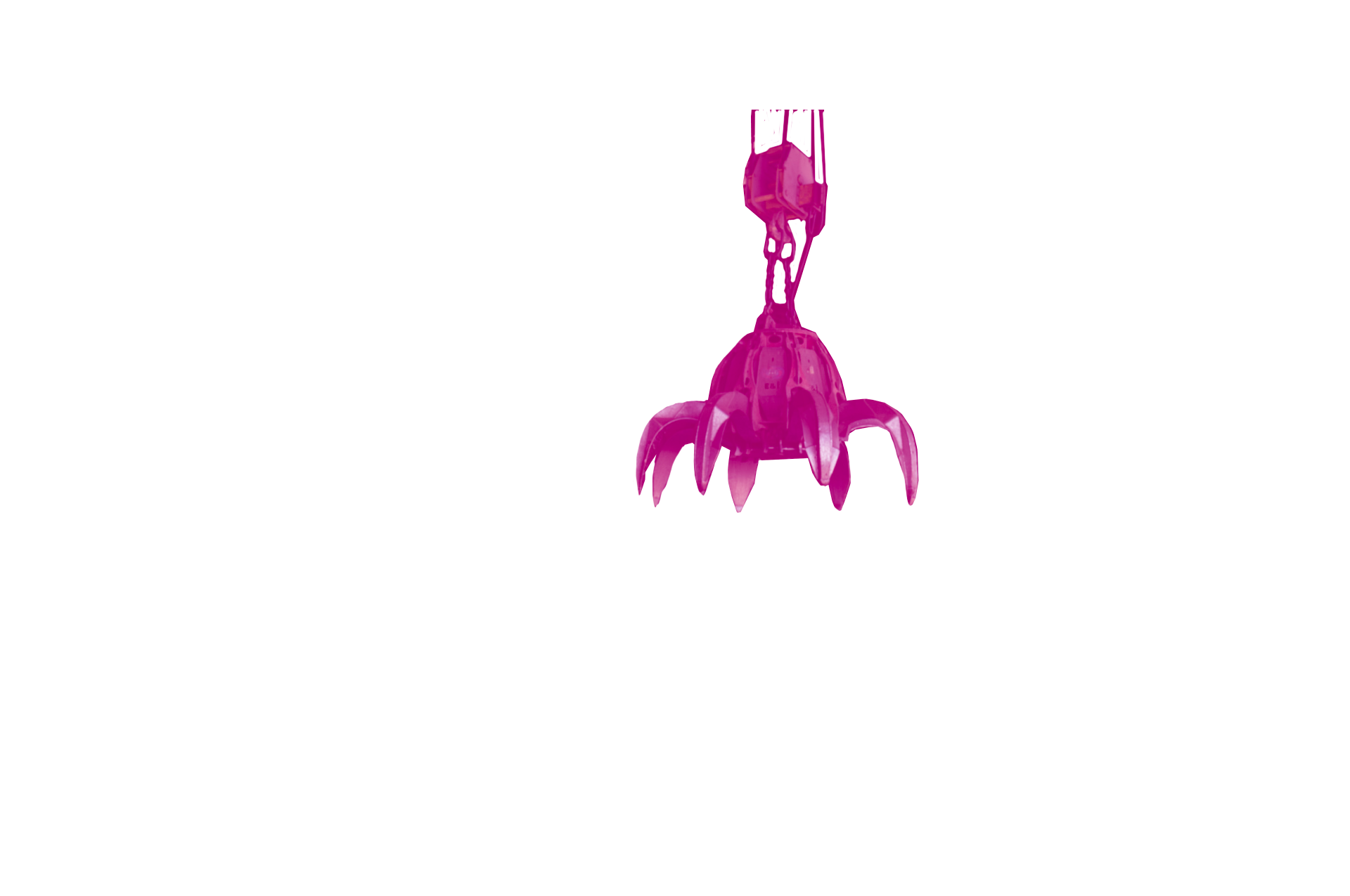

They are loaded into the basket by means of hydraulic spider. The basket is moved by rails from the scrap park to the steel mill.

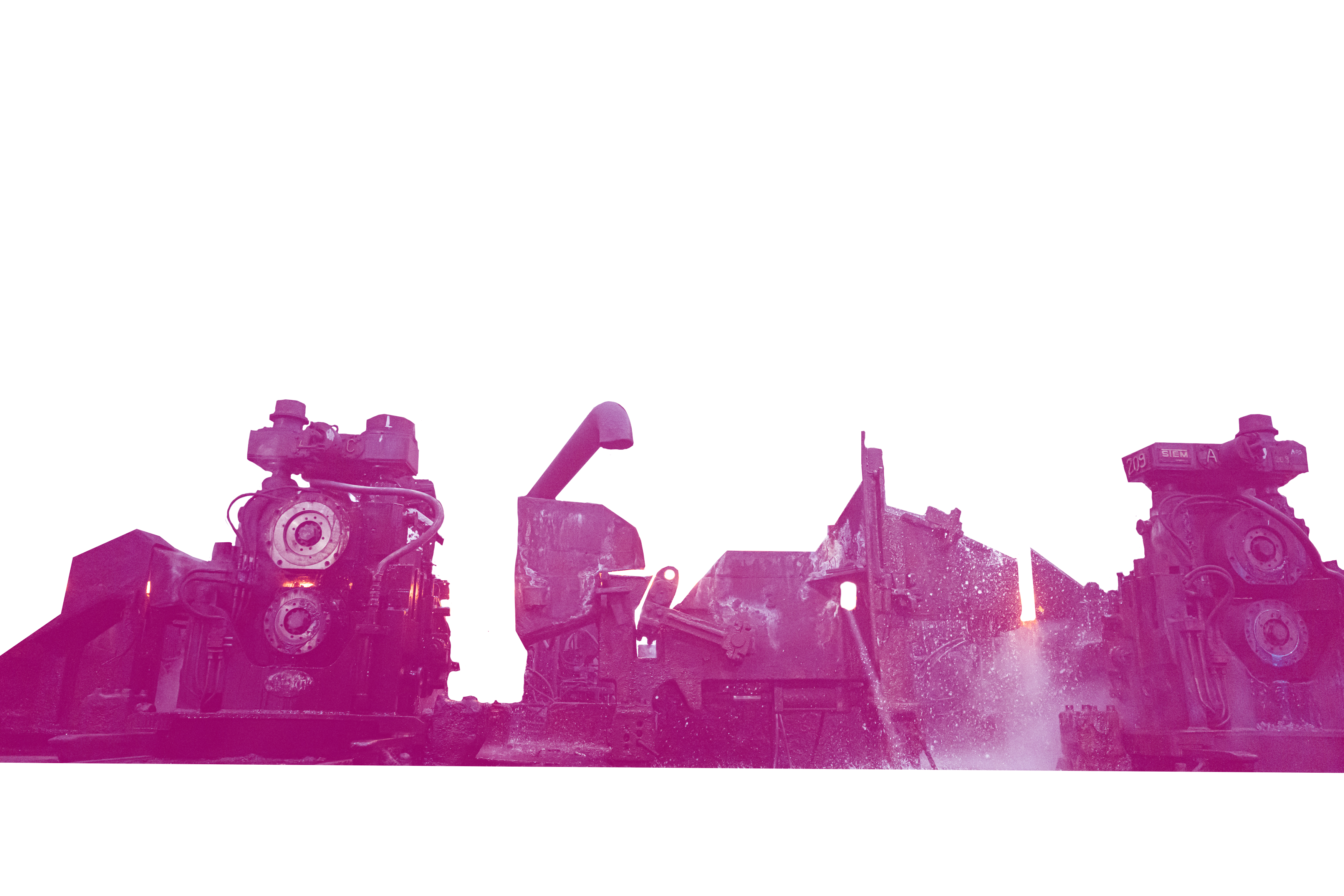

The scrap is melted in the electric arc furnace (EAF) with the addition of lime, coal , ferroalloys and other fluidizers. They are then refined outside the oven.

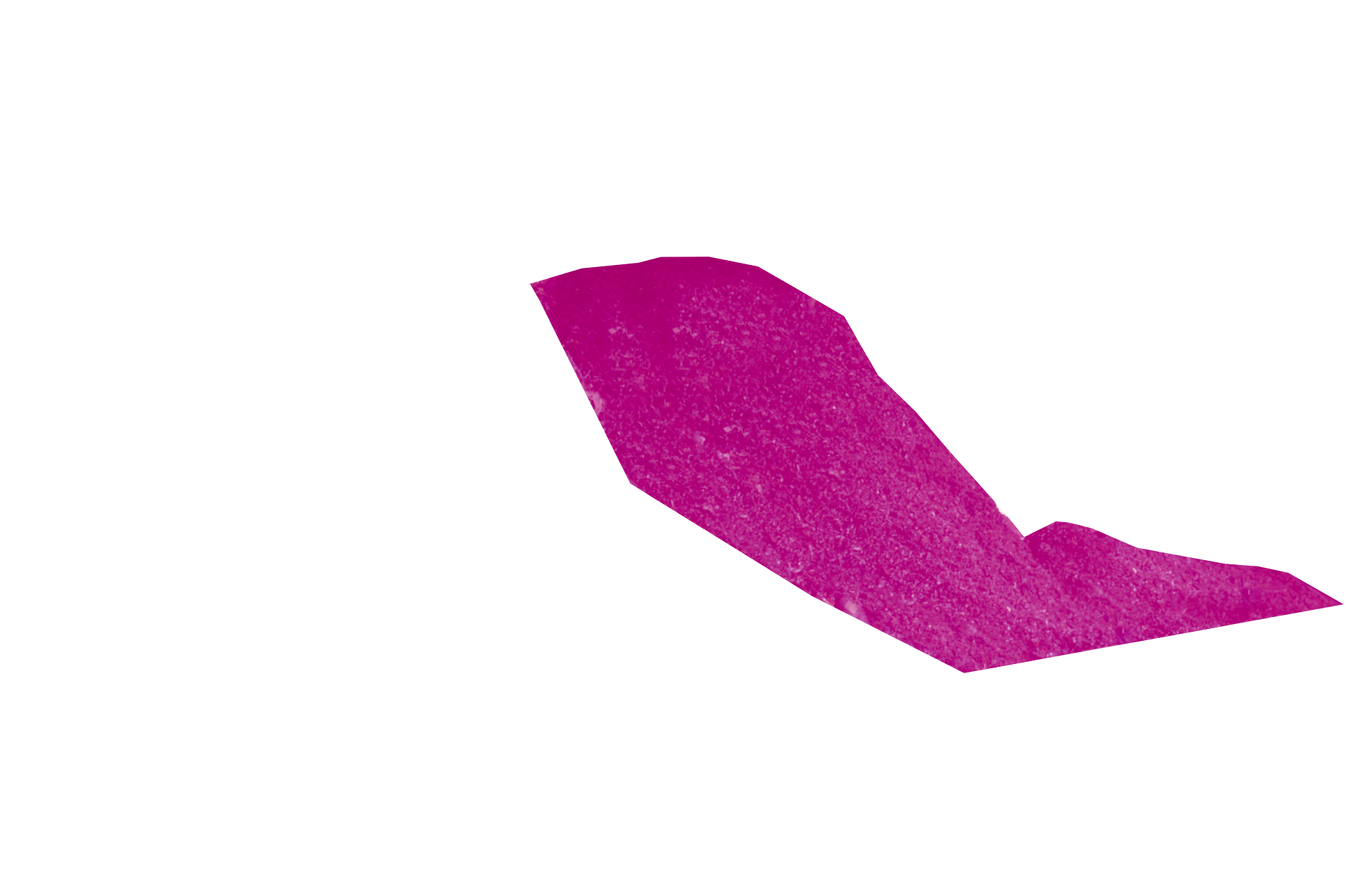

Liquid steel is poured. In continuous casting the steel changes from liquid to solid

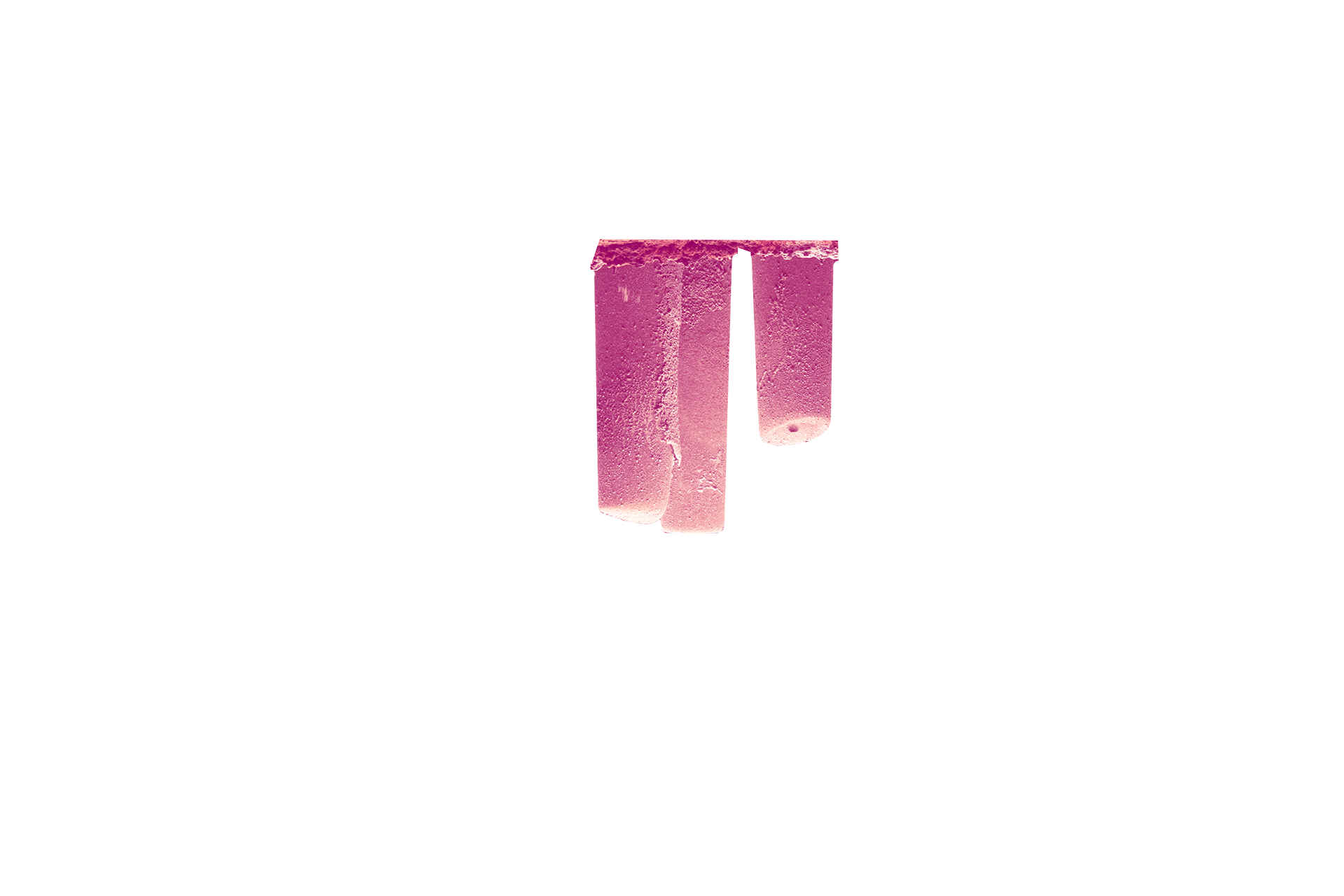

… To form the semi-product called billet or slab depending on the shape.

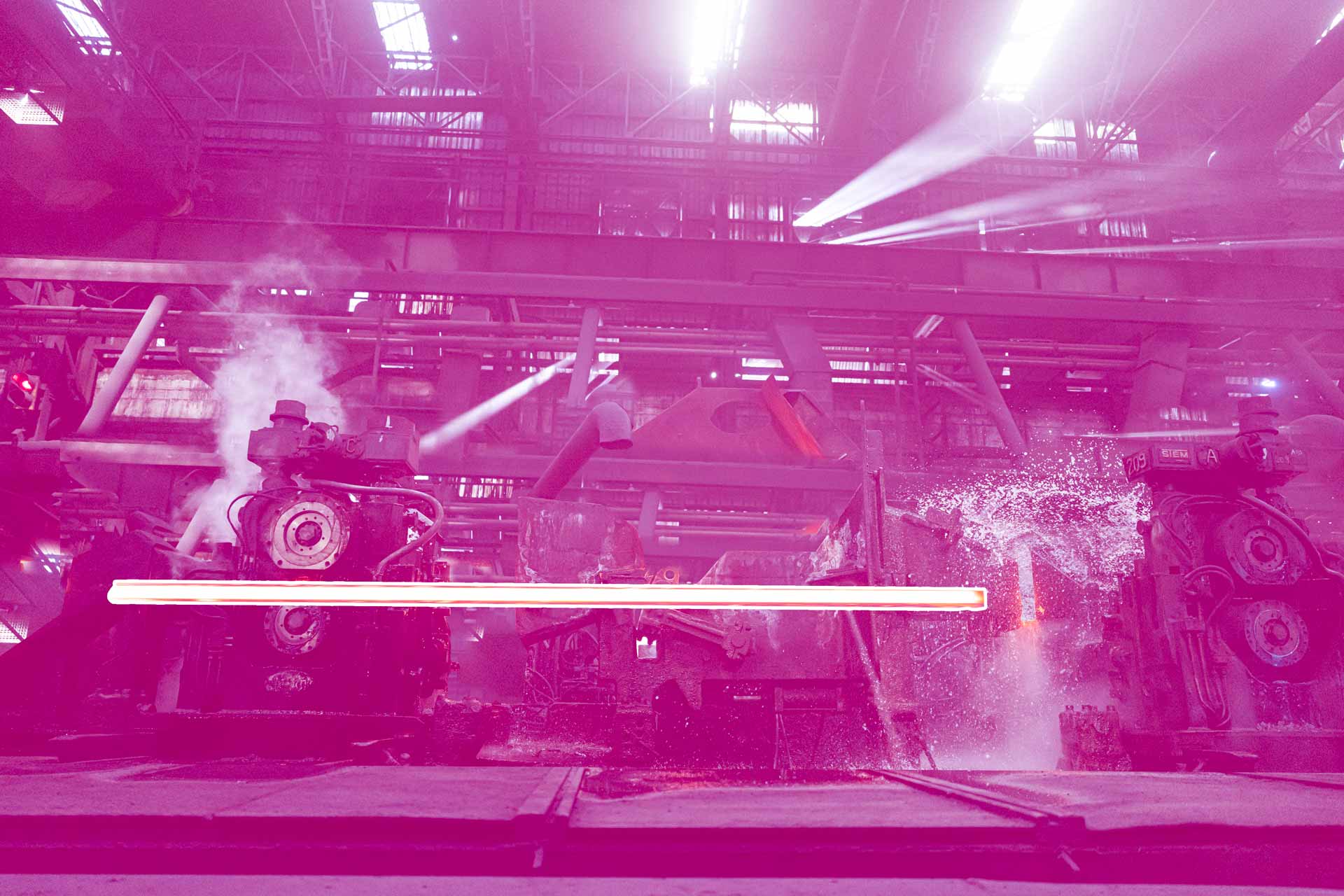

The semi-finished product is heated to be laminated through rolling rolls which give the shape of the final product.

The semi-finished product is heated to be laminated through rolling rolls which give the shape of the final product.

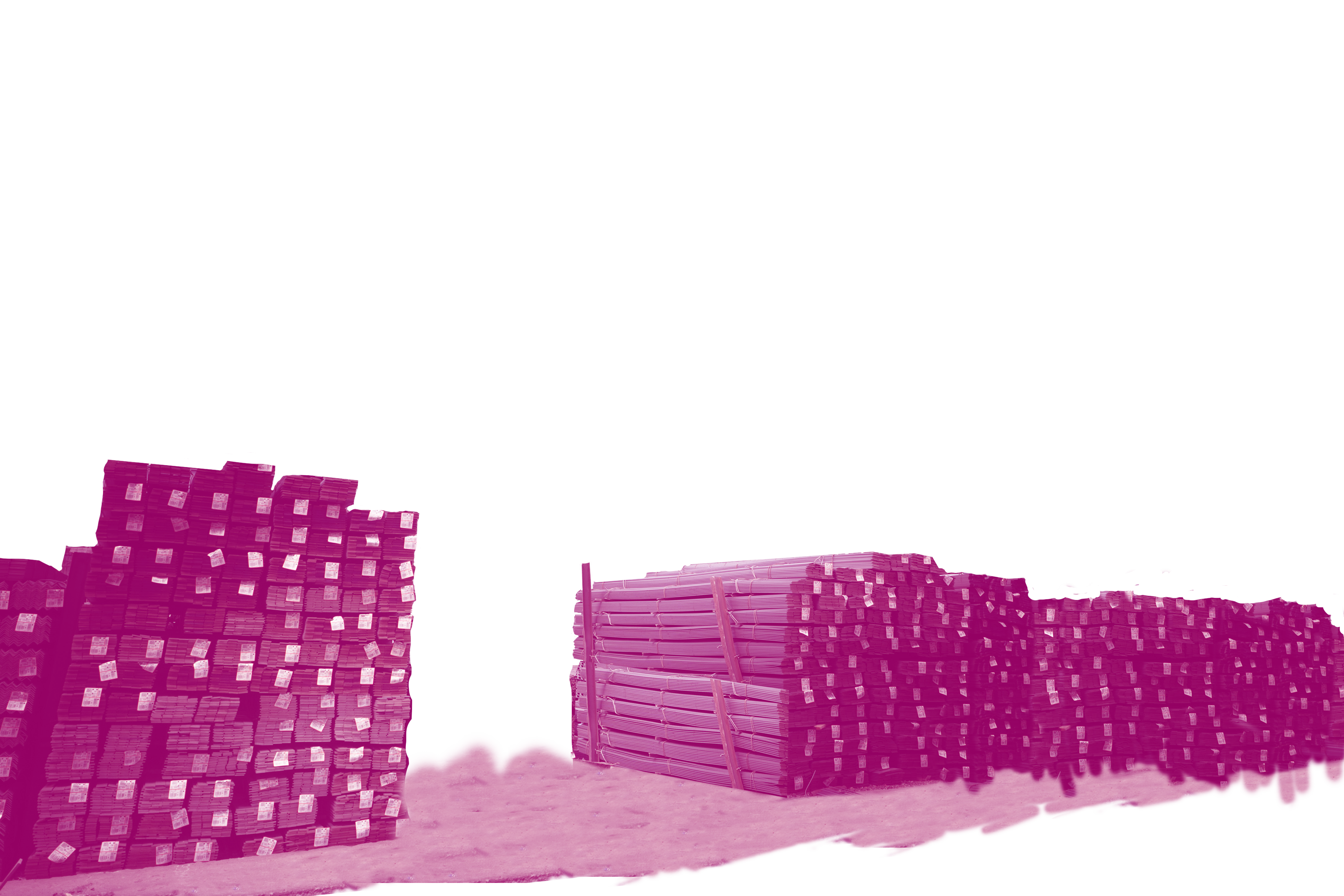

Finally, it is stored in the warehouse, ready to be shipped to customers.

Chalibria’s process