Decarbonization plan

Decarbonization plan to 2030

Offering customers a carbon-neutral product is part of the broader AFV Beltrame Group’s effort of reducing emissions and making operations more environmentally sustainable. Therefore, the Group placed at the very heart of its strategy the Decarbonization Plan to 2030 and a clear roadmap to reduce its CO2 emissions.

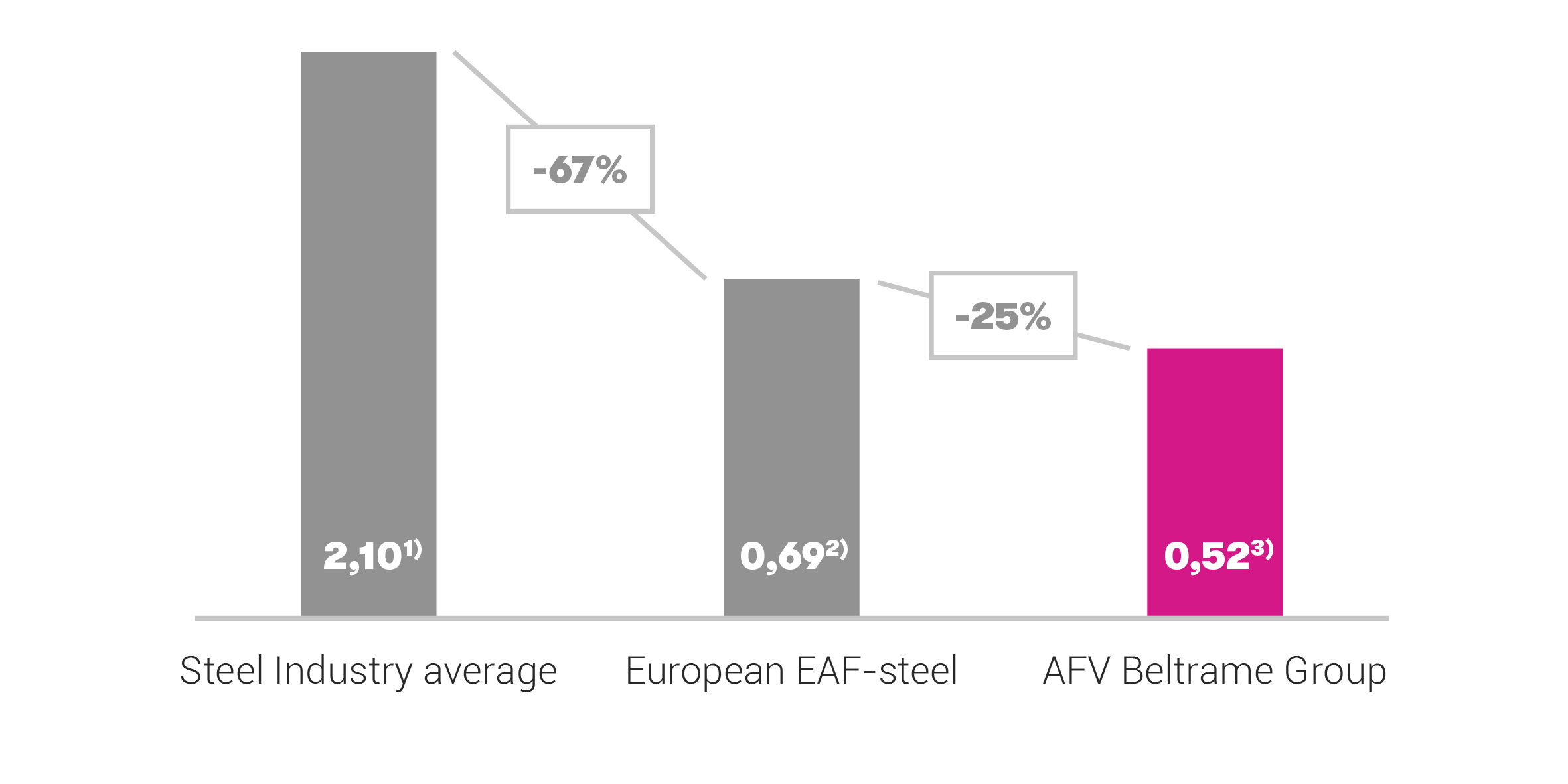

The good news is that the Group already is well positioned. In fact, AFV Beltrame Group’s emissions are well below both the emission average for the steel industry and the European emission average for electric furnace steel (EAF steel), the same manufacturing technology used by AFV Beltrame Group.

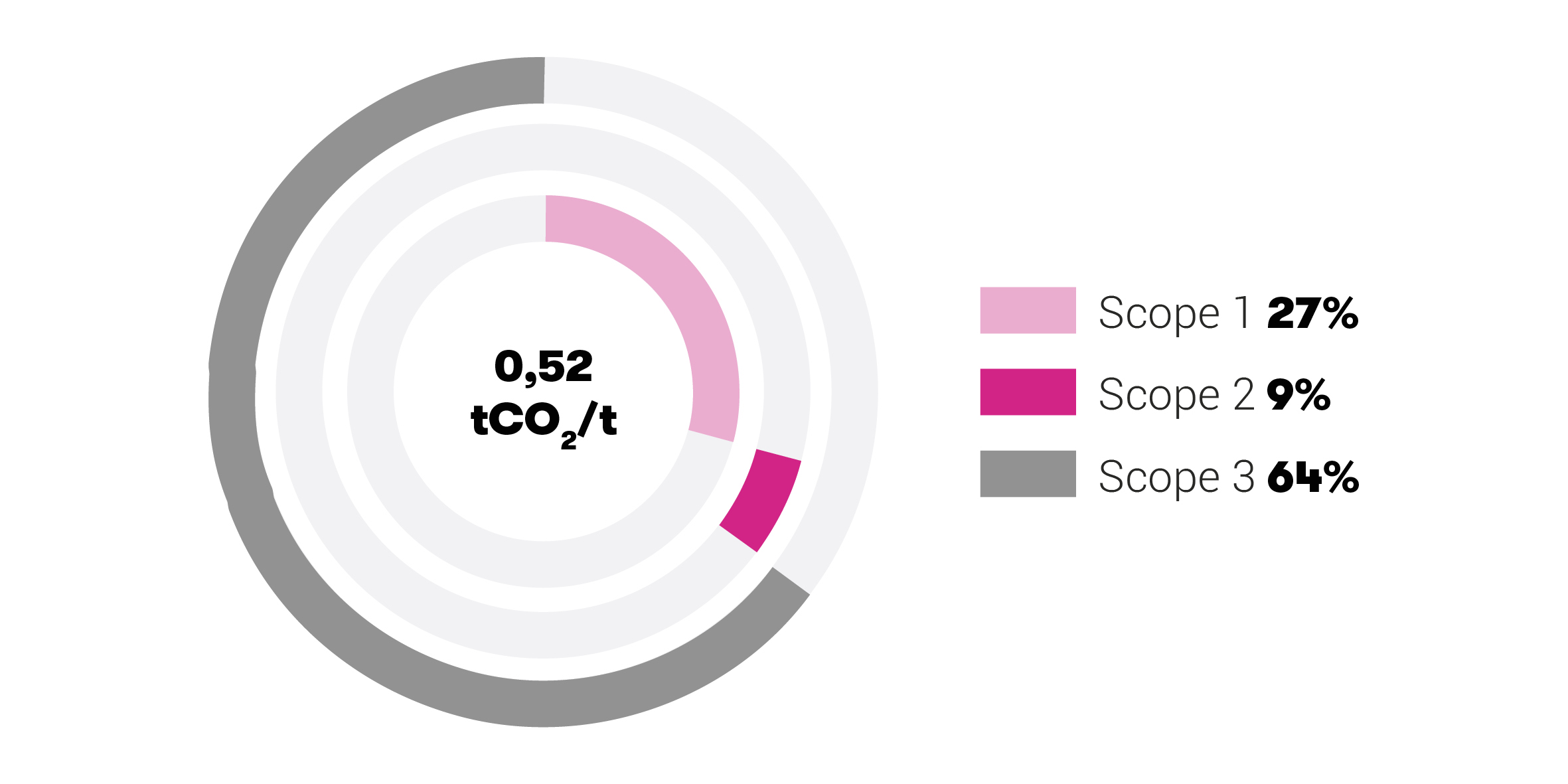

AFV Beltrame Group emission intensity: Scope 1+2+3 (upstream) for melting shop and rolling mill [tCO2/ t finished product steel, 2024]

Comparison AFV Beltrame Group’s emission vs Steel industry average and European EAF steel for Scope 1+2+3 (upstream) melting shop and rolling mill [tCO2/ t finished product steel, 2024]

Sources: 1) Word Steel Association CO2 emission average (Scope 1+2+3 melting shop) integrated with external database CO2 emission average for Scope 1+2+3 rolling mill; 2) European Commission benchmark value ‘21-’25 for EAF carbon steel (Scope 1+2 melting shop) integrated with elaborations based on external database inputs for Scope 1+2+3 rolling mill and Scope 3 melting shop; 3) AFV Beltrame Group Scope 1+2+3 melting shop and rolling mill calculated applying market-based approach for Scope 2.

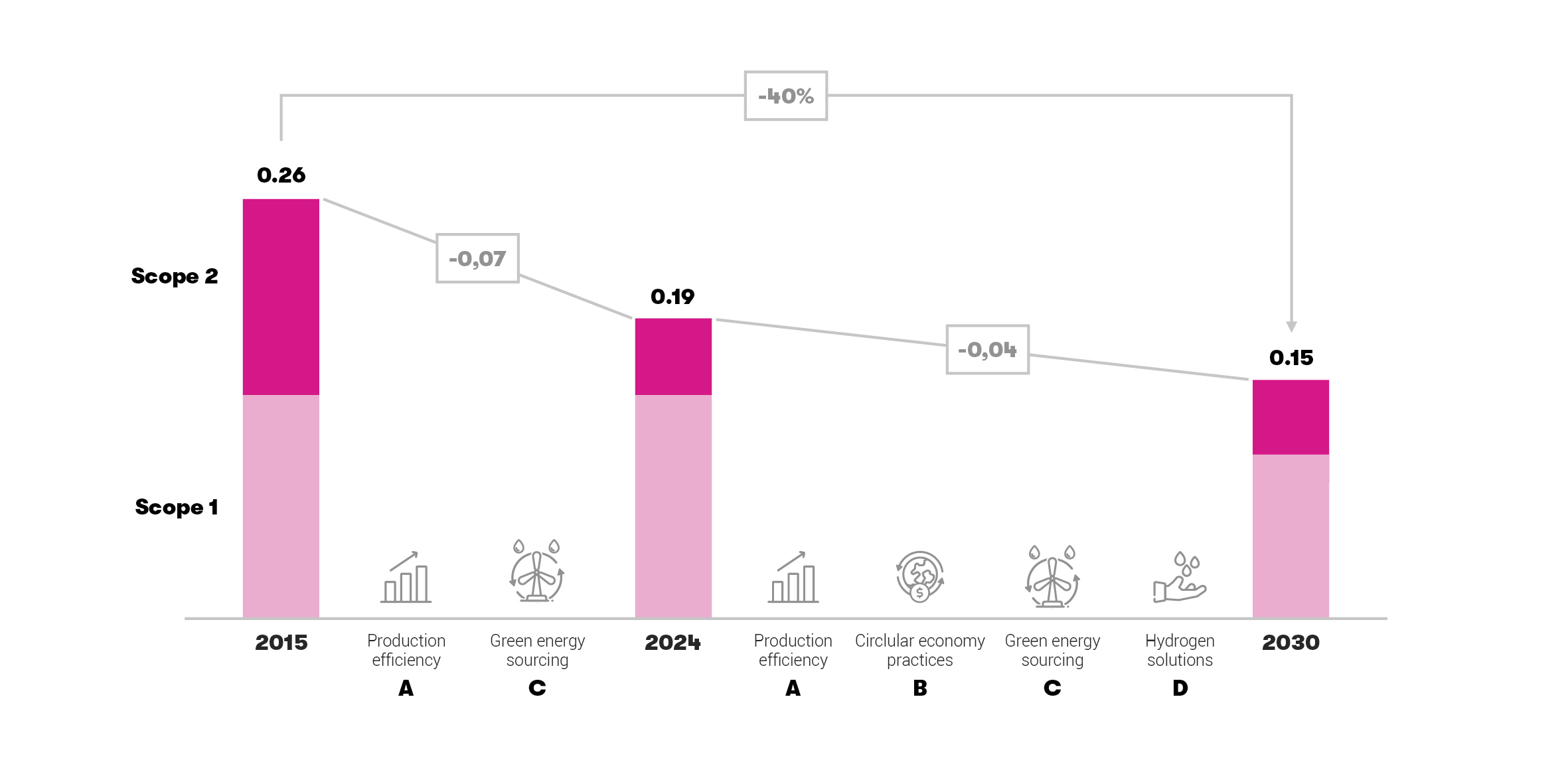

Despite the lower CO2 emissions, AFV Beltrame Group is keen to further reduce its carbon footprint and the Group has set a target to reduce Scope 1 and Scope 2 emissions by 40%.

AFV Beltrame Group’s reduction target for Scope 1 and Scope 2 emissions from steelmaking and rolling mills.

[2015-2030; tCO2/ t finished product]

Many efforts are required to achieve this goal, which is why AFV Beltrame Group has defined a CO2 emission reducing strategy based on 4 drivers: A) Production efficiency, B) Circular economy practices, C) Green energy sourcing, D) Hydrogen heating solutions

projects to improve manufacturing process efficiency, such as revamping reheating furnaces and installing new welding machines

measures to enhance scrap and other raw material quality along with projects to promote reuse of materials of the manufacturing process (e.g., recycled product instead of coal).

projects related to renewable power supply with the development of renewable energy facilities

hydrogen utilization related projects, such as the use of a mix of hydrogen and natural gas in reheating furnaces (starting in 2026)

As for Scope 3 emissions, AFV Beltrame Group has successfully fulfilled emission measurement. The next steps include:

- to engage suppliers, mainly those related to logistics and supply chain, to raise awareness around emission reduction issues;

- to identify, together with other stakeholders within the value chain, initiatives aimed at emissions reduction;