Stahl Gerlafingen AG

530,000

Total area sqm

720,000

Production capacity

steel mill tonnes

620,000

Production capacity

Rebar tonnes

540

Employees

Who we are

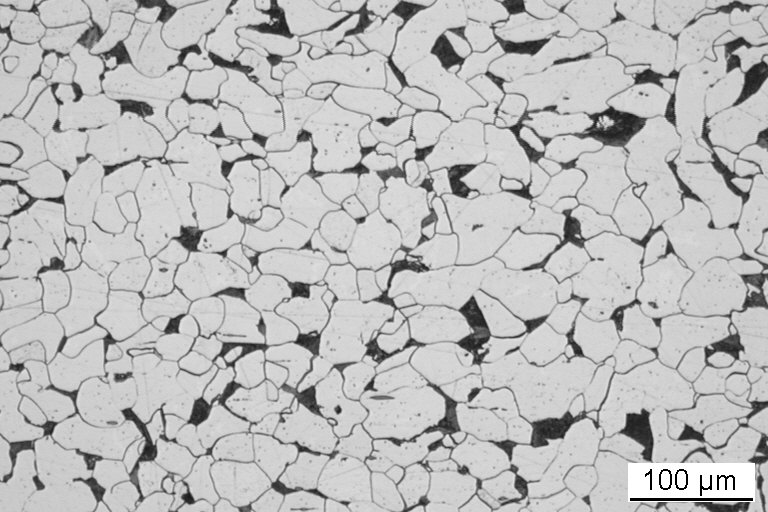

Stahl Gerlafingen is the largest producer of recycled steel in Switzerland and can look back on a great and long tradition at the Gerlafingen site. Reinforcing and sectional steel supplies not only the building construction and civil engineering sectors, but also industry with high-quality steel products. As the largest recycling company in Switzerland, we make an important contribution to the realisation of the future-oriented circular economy in our country. With our investments in efficient production processes, we contribute to low-CO2 steel production in Switzerland.

Our products can be found in buildings, bridges, tunnels, lorries and in a wide range of machinery and equipment in the MEM industries. With around 540 employees, we produce over 700,000 tonnes of steel products every year in uninterrupted 4-shift operation, most of which are used or further processed in Switzerland and neighbouring countries.

High quality, flexibility, and readiness to deliver are our success factors. With 10 to 15 apprentices and trainees, we are committed to the training and further education of young people. In terms of industrial policy, we are committed to attractive framework conditions regarding energy, transport, spatial planning, and the environment. Swiss steel production has a future and is systemically relevant for an active and environmentally friendly circular economy for the secondary raw material scrap in Switzerland and neighbouring countries.

200 YEARS OF STEEL GERLAFINGEN

Visit the page dedicated to the 200th anniversary of Stahl Gerlafingen

Read moreNews

Vision

We achieve our vision of sustainable steel production for the construction and engineering industry in Switzerland and neighbouring countries for the future by consistently focusing on remaining the market leader in reinforcing steel in Switzerland and as a competent supplier of bars and beams within the AFV Beltrame Group.

The needs of our customers, the high quality of our steel products and environmentally friendly and resource-saving production at competitive prices are at the centre of our daily activities.

To achieve these ambitious and demanding goals, we will:

-

- Link the steel mill and rolling mill via roller tables, thereby reducing CO2 emissions by a further 20 per cent.

- Improve rail and road supply through innovative logistics solutions using automated scales, storage space and data management.

- Optimise the efficiency of the energy and oxygen supply to the melting process.

- Examine and implement contracting solutions for in-house power supply by utilising waste heat and photovoltaics.

In the interests of the circular economy, we are also working on utilising the slag produced in a meaningful way. With the development of EOS granulate for road construction, a high-quality recycled construction material, we have developed a solution that has met with great interest.

With these measures, Stahl Gerlafingen fulfils its responsibility for the economy, society and the environment and makes a substantial contribution to the implementation of federal and cantonal strategies on topics such as the green economy, the circular economy, climate protection, energy, and transport.

Mission

We ensure the supply of steel to the construction and industrial sectors in Switzerland and neighbouring countries. Our company is focussed on precision, quality, flexibility, and reliability. High customer satisfaction is our claim.

Our aim is to promote innovation and steady economic growth. At the same time, we take responsibility for society and the environment, which we consider to be core values.

We take responsibility towards our employees as well as our customers. The key to the success of our company is the motivation and expertise of our employees. The health of all employees is our top priority. We work according to the highest occupational safety standards.

We see it as our duty to combine value creation with sustainability. In doing so, we are fully focussed on the circular economy. We recycle 100 per cent scrap for our steel production. Thanks to the use of electric furnaces, our production is low in CO2 and environmentally friendly

We aim to compete with the best in our industry in all areas and are constantly endeavouring to improve. This requires constant optimisation of processes and technologies and continuous monitoring of our own performance.

History

Beginnings

From 1818, there was a plant in Gerlafingen where steel was forged. The foundation stone for the later steel mill was thus laid in the early 19th century.

In 1823, Ludwig von Roll and his partners founded the “Gesellschaft der Ludwig von Roll’schen Eisenwerke” – one of the very first public limited companies in Switzerland.

This was followed in 1836 by the commissioning of a rolling mill – a direct consequence of industrialisation – which increased the demand for iron in Switzerland. The main activity of the plant in Gerlafingen shifted from iron production to iron processing during this period. With the upswing after the end of the Franco-Prussian War (1871), the company grew rapidly. The Gerlafingen site, with direct access to the Emme, seemed ideal. In the years that followed, raw materials were transported to Gerlafingen by water from France, Germany, and Luxembourg.

Expansion

In 1918, the actual steel mill in Gerlafingen was put into operation – ultimately also because of supply bottlenecks during the First World War. Production increased steadily in the following years. During the Second World War, the Von Roll steel mill secured a large part of Switzerland’s supply of iron and steel.

1945 The importance of the steel mill for Switzerland did not diminish after the end of the war. Gerlafingen supplied important material for the construction of infrastructure facilities and transport routes. In the 1960s, at the height of the economic boom, the Gerlafingen steel mill employed almost 3,000 people. The name “Von Roll” remained closely associated with the development of new achievements in Swiss engineering. Thanks to the steel from Gerlafingen, spectacular funicular railways and aerial cableways were made possible.

1973 In the years that followed, the company had to focus on specific markets. Combined with technical advances, this led to an adjustment of the workforce to around 500 employees and 35 apprentices, while production volumes increased over the same period.

In 1996, as part of a reorganisation, Von Roll AG sold Stahl Gerlafingen AG to von Moos AG, today’s Swiss Steel Group.

In 2003, the German group Schmolz und Bickenbach took over the Swiss Steel Group.

International player

Stahl Gerlafingen AG acquired new owners in 2006. With the Italian AFV Beltrame Group, a steel company from Vicenza (Italy) with at least as much tradition took over the majority. At the same time, the company was embedded in a group of companies that is successful on the international market. This allows valuable synergies to be utilised and the company to be optimally aligned for the future.

From 2008 to 2011, new investments totalling around 180 million euros were made in the steel mill and the section rolling mill. As a result, the production line in the Profilstrasse rolling mill was expanded and improved to expand the product segment in profiles and beams and to fulfil customer-specific requirements.

PRODUCTS

People

The key to our company’s success is the motivation and expertise of our employees. We systematically develop and promote their skills through targeted training and further education. The health of all employees is the most asset that must be protected and preserved. Measures to increase occupational safety have the highest priority.

Safe and employee-friendly working environments, occupational safety and health protection are part of our management principles. By creating and maintaining safe working environments that promote health and safety, we contribute to the continued existence and success of our company. We recognise our responsibility towards employees, customers, contractors, and visitors.

We respect and integrate the different cultures of our employees and managers and strive for lasting relationships. We respect and integrate the different cultures of our employees and managers and strive for lasting relationships.

Job opportunities

Job opportunitiesSocial responsibility

Stahl Gerlafingen is one of the largest and most traditional employers in the canton of Solothurn. The endeavours of the AFV Beltrame Group to secure the location, despite the very difficult competitive conditions for heavy industry in Switzerland compared to the EU, can be seen as a clear commitment by a family of entrepreneurs to its social responsibility.

Stahl Gerlafingen offers a wide range of jobs. Employees are currently employed in 30 industrial and commercial professions. The company also trains the next generation in three recognised professions. Every year there are apprenticeships for trainees in business administration, logistics and electrical installation.

Stahl Gerlafingen offers good employment conditions, has signed up to the oldest collective labour agreement in Switzerland, namely that of the metal industry (MEM), and regularly ranks among the best employers in the canton.

Stahl Gerlafingen has been a driving force for integration in the region for decades. While in the beginning it was Italians from Tuscany who came to Gerlafingen as foreign labourers and were soon allowed to bring their families with them, today the plant employs people from 39 nations who produce steel together.

Environmental responsibility

As a progressive employer, the company recognises its responsibility towards people and the environment. We strive for continuous improvement through process optimisation and investments. This enables us to reduce environmental emissions and the consumption of energy and resources. Already before the takeover by the AFV Beltrame Group, the steel mill in Gerlafingen had invested millions in environmental protection. This has massively reduced the various emissions caused by heavy industry operations. The AFV Beltrame Group also continued along this path, investing considerable financial resources in further improvements. The Gerlafingen steel mill is also in active dialogue with the authorities and the local population. The demands of the federal government, the canton and the municipality are being implemented. To this end, Stahl Gerlafingen cooperates with the authorities.

Stahl Gerlafingen plays an important role in the recycling of scrap and the supply of steel products in Switzerland. Our company closes a nationally important recycling loop at the Gerlafingen site. It also performs an important supply task for our country in the future, thus avoiding unnecessary transport on our road and rail network.

Safety

As in all other areas (productivity, quality, energy and resource efficiency, costs, and the environment), we also want to compare ourselves with the best in our industry when it comes to occupational safety and constantly improve. This includes keeping our filtration systems, radioactivity detection and noise protection up to date with the latest technology.

Corporate governance

For the AFV Beltrame Group, corporate governance is the entirety of the values, principles, guidelines, rules, practices, and processes according to which Stahl Gerlafingen AG is managed, operated, and controlled. The aim is to ensure the efficiency of the company, increase growth and promote investor confidence in a national and international context through practices aimed at transparency and consistency of actions. The aim is to gain the respect of those who invest in the company. At the same time, however, the fulfilment of obligations towards the various interest groups should also be guaranteed.

Achievements

Since acquiring the majority shareholding in 2006, the AFV Beltrame Group has gradually modernised the Gerlafingen site and intends to continue doing so. The investments not only serve to secure the future of the plant in the face of international competition, but also to increase the efficiency and climate compatibility of the production site.

What we have achieved since then is impressive:

2018 to 2020 As part of an efficiency improvement programme, the steel mill invested in specific solutions for better logistics. For example, in the easier handling of reinforcing steel in bars. The new system was put into operation in September 2020. New scales for railway wagons and trucks also went into operation. This has significantly improved the supply and removal of goods by rail and road. Processes have been improved and partially automated using state-of-the-art technology. This allows for optimised production steps and increases the safety of our employees. The drawing and stretching line put into operation in September 2020 has improved productivity and quality in the further processing of wire rod into semi-finished and finished products.

2021 to 2023 We have begun a medium-term, strategic investment programme to comprehensively upgrade the facilities to produce reinforcing steel and bring them up to the state of the art, as was done in 2007-2011 for the section rolling mill. The first supply contracts have been signed. The new plant will allow continuous rolling on this production line, which was previously not possible. This will make the line more productive and, above all, more efficient in terms of energy consumption. The first stage of the investment in 2021 will see the demolition and rebuilding of the existing line. The plant has been ordered, the building applications have been submitted and realisation will take place in 2021. The project will involve a total investment of around CHF 7.5 million.

To improve energy efficiency, a new combined pusher furnace to produce reinforcement steel will be realised. This investment will increase the capacity of the rolling mill and at the same time substantially reduce the consumption of fossil fuels using heat and burners with the latest technology to minimise CO2 emissions. Just as was done with the new furnace as part of the first investment programme.

Finally, Stahl Gerlafingen is looking to make additional investments in the plant infrastructure. This will also involve using the site for future-oriented partnerships, such as with H2 mobility, which wants to realise a network of hydrogen filling stations in Switzerland.

Contacts

STAHL GERLAFINGEN AG

Bahnhofstrasse, Postfach

CH-4563 Gerlafingen (Switzerland)

Ph. +41 (0)32 674 22 22

Fax +41 (0)32 674 28 39

info.ch@beltrame-group.com

SALES DEPT.

Fax +41 (0) 32 674 2846